What is Spray Freeze Drying?

Spray freeze drying is a unique and emerging technique that is used to turn liquid suspensions and solutions into solid powders. In doing so, it combines two more common and conventional methods — spray drying and freeze drying — into one for more efficient process and higher quality product.

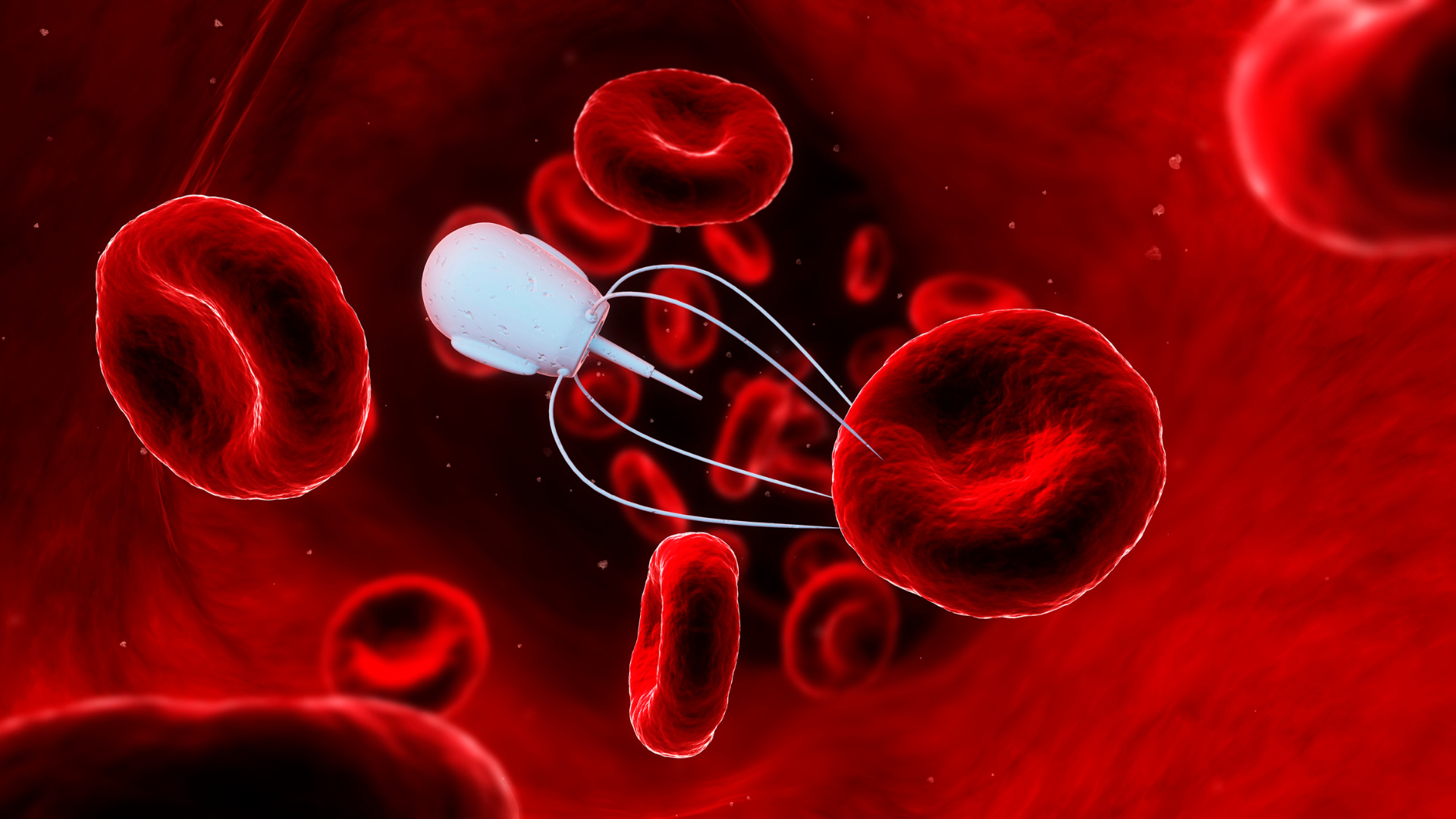

Here, the process can be used for the drying of pharmaceutical products. Furthermore, due to the aerodynamics and low water soluble encapsulation of the porous particles that are produced, they are especially suited to use in the delivery of drugs directly to the lungs.

- Advanced Formulation Development Strategies & Towards Sustainable Lyophilisation

- New Freeze-Drying Technologies: Pfizer’s Quest for Sustainable Cooling

- Vanguard Strategies: Perspectives on Developing Novel Pharma Technologies

There are three steps that make up the spray freeze drying process: atomizing a liquid or solution into droplets, solidifying them through contact with a cold fluid, and subliming those particles at low temperature and pressure.

For each of the three stages of spray freeze drying, there are several methods which can be employed to achieve the desired effect.

The atomisation process breaks up bulk liquids into small droplets, which can be achieved using a nozzle to spray the liquid. Types of these nozzles include one fluid, two fluid, or ultrasonic nozzles.

The second stage of spray freeze drying is the freezing stage. Rapid freezing is usually achieved using a cryogen such as liquid or gas nitrogen, its rapidity helping to prevent phase separation of the biomolecular structure.

The final stage of the process employs freeze drying techniques to sublime the particles. Here the frozen powder is removed from the spray-freezing apparatus to be dried. The droplets are usually dried into particles using a vacuum.

Spray freeze drying has the potential to enhance operational efficiency and the quality of the end product. This improvement stems from the heightened heat and mass transfer occurring during the drying phase, attributed to the expanded surface area of frozen particles.

However, the transition of scaling up this process for commercial production is expected to be a complex undertaking, primarily due to various constraints at each stage. Addressing this challenge may involve the development of innovative technologies tailored for continuous manufacturing, which appears to be a viable approach for adapting to the evolving industry landscape while considering the practical aspects of scaling up.

Get your weekly dose of industry news and announcements here, or head over to our Formulation portal to catch up with the latest advances in manufacture and therapeutic delivery. If you’d like to learn more about our upcoming Formulation and Delivery US event, click here to download an agenda or register your interest.