“Stability Can be a Problem” — Dealing with Nanoparticle Stability Challenges in Drug Formulation

Formulation & Delivery US 2022 featured one panel discussion that focused on Overcoming Stability Challenges In Drug Formulation. With new modalities and delivery methods ever increasing, making sure that vectors and drug cargo are stable in their formulation is a vital factor to consider en route to regulatory approval. The panel of experts all had experience with drug development and specialised in different domains within formulation.

On the panel was Kejin Zhou, Founder and CEO of Reinvigoron TheraTech Inc., who works in nanoparticle product development; Larry Wigman, was formerly Vice President of Analytical Research and Development at Pfizer, with extensive experience working with small molecules. Also joining was Mick Hurrey, Vice President of Product Development at InCarda Therapeutics, who specialises in combination product development.

The Impact of Cholesterol Oxidisation on Stability

One particular challenge when dealing with stability is the fact that the cholesterol component of lipid nanoparticles (LNP) can be prone to oxidation. With regards to this difficulty, the panel were asked “what is the impact of oxidation on the stability of other quality attributes regarding the particle’s size, aggregation, and degradation?”

Zhou commented that LNPs commonly have multiple components to fine-tune their hydrophobicity. “Cholesterol also has a hydrogen group, that’s how it oxidises,” he said. Therefore, for aggregation, a PEG-lipid may not be enough to cover the hydration that is needed.

“It may depend on the process,” Zhou added. His experience had led him to believe that cholesterol was actually very stable, “so if it oxidises it might not induce aggregation.” He further commented that oxidation impacts an LNP’s mobility and therefore it was very important to pay attention to how that impacts controlled release delivery.

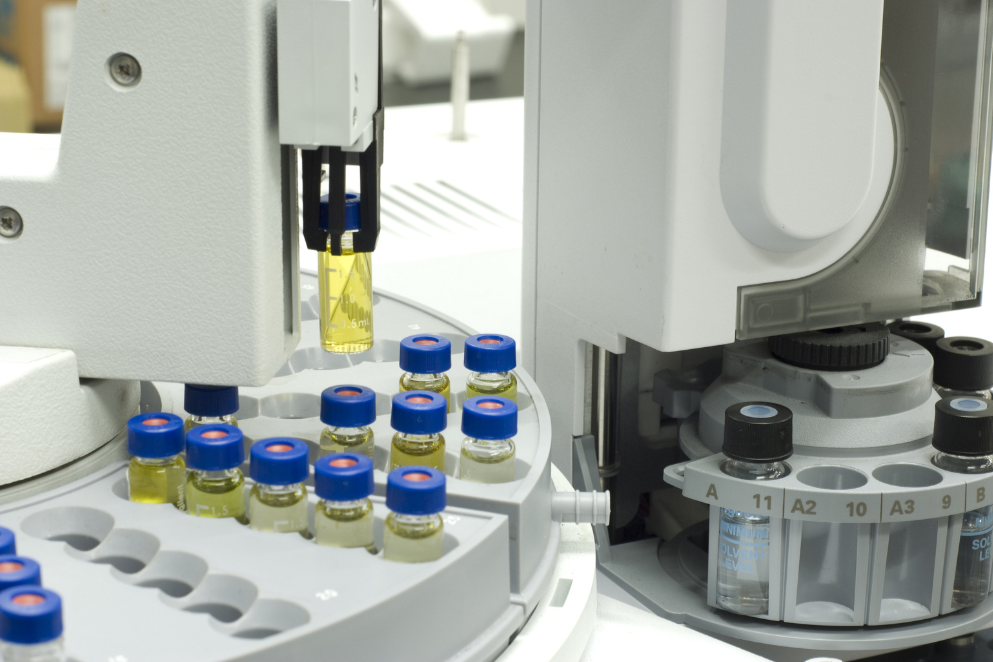

An audience member contributed that the FDA was becoming increasingly concerned about stability, and one particular concern was cholesterol oxidation — “so you should definitely measure it.” He used liquid chromatography–mass spectrometry (LCMS) to measure this but didn’t find any measurable oxidation of cholesterol.

‘Regulatory Science’

“This is what I call ‘regulatory science’,” said Hurrey. “— questions from the regulator that are more about regulation than science.” For instance, he suggested that a regulator might ask a lab to look for nitrosamines with a compound that has no nitrogen. “It’s not ideal but the best option you have is to just measure it. You can make the case for why you don’t need to do it, but the regulator is still going to ask you to do it.”

One audience member also pointed out that there may be a physiological reason to monitor such properties, that being that hydroxylated lipids will traffic differently once they are in systemic circulation. Therefore, there may be situations where a drug travels to an unintended place in the body and have inadvertent effects.

Hurrey clarified that sometimes a regulator will ask for parts of a formulation or storage that aren’t possible, “but if it’s a physiological thing, that’s a different matter.” Hurrey said that he “totally agreed” that there are certain metabolic pathways which need to be taken into account when working on drug formulation and delivery: “you have to consider the entire biological soup.”

Drug Loading and Nanoparticle Stability

The discussion then turned to the stability of drug loading in nanoparticles. Zhou said that this problem came in two parts: the first is the stability of the nanoparticle itself, and the second is the stability of the cargo.

Working on the drug loading stability of nanoparticles involves a careful balance between stability of the drug product, delivery to specific target tissue, and the controlled and constant release of the active component. Wigman explained that “stability is all those three different parts together and it’s a real fine balance.” He said that the formulation development challenges occur in finding the control point: “Is it in the bottle? Is it releasing the drug? Is it delivering to the right tissue?”

- Key Strategies and Challenges for Lipid Nanoparticles

- “Teaching Old Drugs New Tricks”: Repurposing Therapies Using Nanoparticle Delivery

When loading a drug, be it a small molecule, peptide, or mRNA into a nanoparticle, the stability of the payload is brought into question during the loading process.

During storage, there is a possibility that the payload can leak out of the nanoparticle into the formulation. This leaves the drug free in solution rather than encapsulated by the nanoparticle. Zhou confirmed that the drug will always have a tendency to diffuse outside of the nanoparticle, from a high concentration to a low concentration. He suggested that hydrogen bonding could be to keep the drug in the nanoparticle and protect the stability.

Drugs loaded into a nanoparticle eventually get administered into the body. Therefore formulation scientists have the paradoxical wish for controlled release while in vivo, but stability during the storage. This can be tricky to achieve, but Zhou suggested that lyophilisers could be used to try and make it stable.

Functional Excipients for Specific Pathways

Wigman announced that one of the underlying themes of the talk so far was that “stability can be a problem.” Therefore, he stressed the importance of having a good understanding of the right analytical tools and using them to find out what will be stability limiting in a formulation.

“For small molecules, its usually something along the lines of a chemical degradation. But with biomolecules and nanoparticles, physical changes, aggregation, oxidation, or hydrolysis can all affect delivery.” Therefore, Wigman recommended that “understanding what problem you’re trying to solve is always the best place to start.”

For instance, Aspirin hydrolyses and becomes toxic upon exposure to moisture. In light of this problem, Wigman suggested that formulation scientists opt for dry-processing, dry conditions, the use of desiccants, and moisture protective coatings.

Furthermore, Wigman spoke about working with biologics, reiterating the need to understand the problem in question. “If you’re having trouble in your freeze-thaw cycle, you lose a lot of activity, you may need to protect from sheer during freezing,” he said. “So you’re using trehalose, you’re using surfactants; selecting those types of excipients is based on the mechanism.”

Check out Oxford Global’s Formulation & Delivery conference. Learn from and meet leading experts in pharmaceutical science, addressing the critical strategic advances and technical innovation in formulation, drug delivery and drug product development.