Challenges in the Formulation of Biologics: Protein Aggregation, Safety, and Technology

The formulation of biologics produces a unique set of challenges due to the high-order structures of biologic molecules. If a protein is unstable, denatured, or otherwise chemically altered, an affect could be severe safety concerns due to protein aggregation causing undesirable immunogenicity. At Formulation UK 2022, Oxford Global was pleased to host an eminent panel discussion on Overcoming Challenges in Formulation Development of Biologics, which discussed protein aggregation, safety, and new technologies to address these concerns.

What Control Measures Can be Put in Place to Address Protein Aggregation?

On the topic of aggregation, Kishore Ravuri, Chapter Leader Pharmaceutical and Processing Development at F. Hoffmann - La Roche, said that it used to be a bigger concern than it is now. Since then, a lot has been learned about aggregation, but it still remains something that needs to be watched carefully throughout development. “It boils down to safety which needs to be tested during the trial as well,” Ravuri explained, “and the final set of specifications that are acceptable to the health authorities.”

Ravuri recounted how researchers’ understanding of immunogenicity had grown over recent decades: “we know that not all aggregates are equal, and that photodegraded aggregates have been established very clearly to cause immunogenicity.” Ravuri said that this lets other kinds of aggregates which occur due to interfacial interactions “off the hook.”

- Advanced Vaccine Platforms & Technologies

- Handle with Care: Continuous Delivery of Fragile Molecules

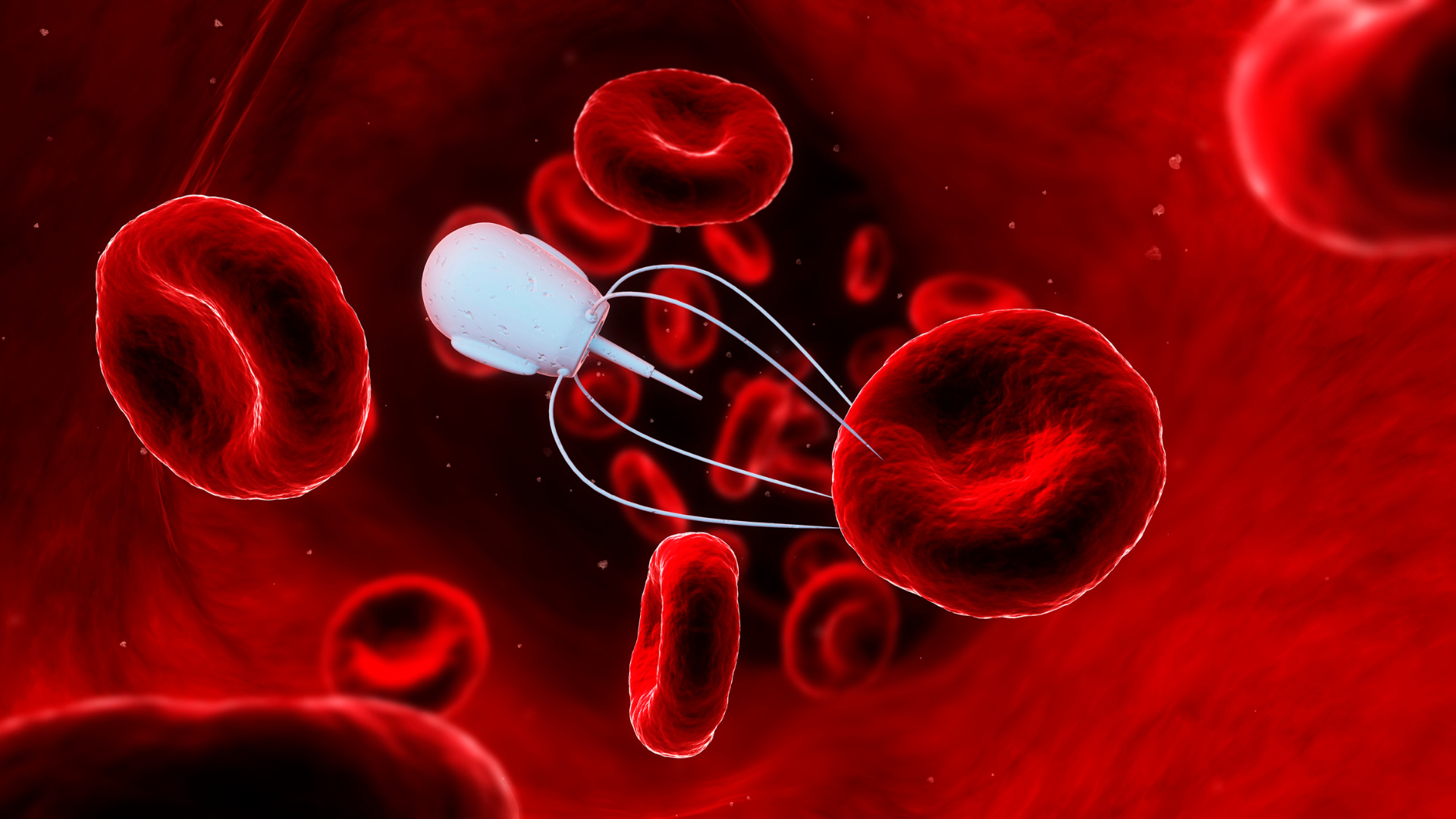

- Technologies Advancing Drug Delivery Through the Blood-Brain Barrier

Nicholas Darton, Associate Director at AstraZeneca, commented “Indeed, for typical platform mAbs, aggregation is quite well understood.” Darton added that mitigation approaches are in place to tackle aggregation as it occurs.

“There is a lot known about safety of aggregates,” Darton continued, “but as we’re developing novel modalities and new constructs, certain aggregation issues have reared their head again.” “We have our existing toolbox of excipients and formulation approaches to throw at these new aggregation challenges,” he explained. Although the scale of the problem that aggregation presents is not as enormous as it was before, it can still pose issues for developing new products.

Antibody Aggregation

Eleonora Toffoli, who is a Senior Expert of Science and Technology at Novartis, said that “we know quite a lot about antibody aggregation. But still, we need to think about the new excipients which we add to stabilise the protein.” It is important to figure out if the new excipients that Toffoli mentions are safe – “and in terms of concentration, what toxicity range can we use?” Toffoli explained that the quality of the excipients was key to this: residuals that induce aggregation can be circumvented in proteins.

Toffoli added that aggregation for viral vectors is not a problem for the product itself, despite aggregation, most viral vectors are still functional. However, aggregation is a big challenge for manufacturing, strong yield loss at filtration and concentration steps are shown. More efforts is needed to improve the manufacturing process.

Thermal Degradation of Polysorbate

Darton then weighed in on the topic of safety, commenting that particle formation can result in immunogenicity, and that polysorbate degradation can be problematic for this particle formation. “That process can be accelerated by the presence of host cell proteins,” Darton further explained, “– like lipase and esterase – they break down the polysorbates.”

One challenge for researchers is that sometimes this only becomes apparent after six months of stability: “so, some of the decisions that are made from the early stability data will need to be adjusted if host cell proteins are identified to be a problem in the stability of a product.” Host cell proteins are a familiar talking point among formulation researchers, especially considering their impact on host cell product quality.

“There are a number of techniques currently being used,” Darton claimed, “including mass spectrometry for detailed analysis of host cell populations in drug products.” This can be employed to help formulators overcome these product quality issues with new solutions. An example that Darton gave was the substitution of polysorbates with poloxamers.

Ravuri chimed in on this topic by focusing on the free fatty acids that come out of polysorbates. “We have clear signals coming out of health authorities that these free fatty acid particles are not acceptable,” he said. He clarified that this is not necessarily due to safety concerns, but more to do with it alerting health authorities. “The authorities are not convinced that the process is under control – especially with regard to host cell proteins,” Ravuri explained. Therefore, there is a demand from those agencies to be tight on controlling polysorbate degradation: “because it’s a signal for lack of control on the DSP or USP levels.”

Ravuri recommended caution when linking immunogenicity to the formation of aggregates when there is decreased polysorbate content. “This is something which has come up in the literature a couple of times,” he said. Ravuri promotes the claim that this formation of aggregates is because of interfacial instability due to a decrease in polysorbate content: “In those cases, we will need to go back to the drawing board to ensure that we can put in enough upfront – factoring in the amount of loss that might occur.”

There are also other potential protein issues with particle formation. Ravuri pointed out cases of companies releasing drug products that say ‘may contain visible particles’ on their packaging. “This happens when the sponsor company finds out what those aggregates are, shows patient exposure, and points out how many particles are potentially formed, up until an end of shelf-life scenario.” Ravuri commented that in these situations, health authorities have actually accepted those visible particles as inherent to the product – hence the inclusion of a label on the packaging.

It is important for the development of the formulation of biologics that its nuanced challenges are met with innovative solutions. Improving upon formulation and the problems that safety and aggregation pose to it is a vital task for researchers working with biologics. That’s why it was fantastic to host our panel discussion on this topic at Formulation UK 2022.

Join leaders, experts, and researchers at Formulation & Delivery US: In-Person, connecting global pharma, biotech, and academia for high-level discussions on the latest innovations for biopharmaceutical development.