Sustainable Synthesis of Therapeutic Oligonucleotides

Our March group came together for an hour of specialist discussion about the current state and future directions of green synthesis for oligonucleotide therapeutics. This Discussion Group was a select group of key industry leaders from various pharmaceutical and biotech companies, as well as renowned academic institutions.

Louis Diorazio, Senior Principal Scientist of New Modalities at AstraZeneca, led the discussion, whilst Martin Olbrich, Principal Scientist at F. Hoffmann-La Roche and Ben Andrews, Investigator in Chemical Development, Product Development and Supply at GSK, were there to support. Key discussion topics included synthesis design for large-scale manufacturing, optimal synthesis methods for pharmaceutical practice, and technical challenges of solvent and water consumption.

Notable attendees included senior representatives from Sanofi, Silence Therapeutics, Janssen, Galapagos, Ionis, Arrowhead Pharmaceuticals, and Biogen. Academic attendees were professors from the University of Oxford, Queen Mary College and University College London.

Sustainability Considerations for High Volume Oligonucleotides:

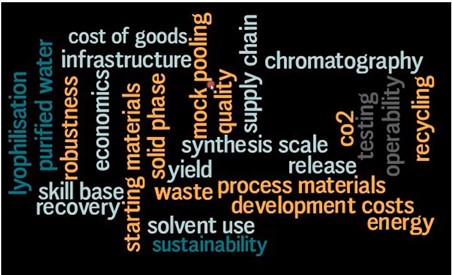

Diorazio kicked off the session with a brief overview of the current industry trends and strategies for conducting large-scale synthesis. Entitled, ‘Sustainability Considerations for High Volume Oligonucleotides,’ the presentation alluded to market concerns about the broader environmental implications of high-volume manufacturing. These concerns were identified as waste production, access to materials, and economic footprint (see figure. 1).

Diorazio identified AstraZeneca’s definition of sustainability as: “implementing our strategy and delivering the target we have set ourselves in a way that promotes the long-term health of AstraZeneca, the societies in which we work, and the planet.” However, oligonucleotide scale-up presents numerous challenges for sustainable manufacturing.

Increased solvent and energy use are among the top impediments to optimised and needs-based oligonucleotide synthesis. Solvent use can be hazardous, whilst energy-intensive operations are both timely and costly. “Whichever way we address oligos, there will always be things that will create a negative impact,” Diorazio stated. However, there are strategies available to offset sustainability concerns.

Sustainable Purification for High Volume Oligonucleotides:

Tagged solution synthesis, blockmer approaches, and (non-)templated biocatalysis are among the most promising sustainability solutions. “There are certainly opportunities when it comes to synthesis of oligos, and a general rule is that better synthesis means better purification,” Diorazio explained. Cleaner material input allows for better purification outcomes and lightens later analytic burdens.

One example of sustainable technology for purification includes continuous chromatography that uses multi-column solvent gradients. According to Diorazio, this approach provides “a way of getting more material out from your chromatographic activity.” Furthermore, there has been considerable interest in continuous chromatography from Contract Manufacturing Organisations (CMOs) delivering large volume oligonucleotides.

Sustainable Processing and Conjugation for High Volume Oligonucleotides:

Integrated substance and product processing present an ambitious and compelling opportunity for high volume manufacturing. As a toolbox approach, this application offers a robust workflow and reduces the overall cost of goods. The integrated approach removes the need to freeze drug products, which lessens the chances of degradation and loss of valuable samples.

Diorazio explained how “conjugation enhances sustainability performance through absolute footprint reduction.” Although conjugation adds significant complexity to manufacturing processes, it facilitates dose reduction. For example, Diorazio divulged AstraZeneca’s findings that a 5’-GaINAc conjugation adds approximately 66% additional material consumption compared to a naked oligonucleotide but reduces manufacturing volume by >5-fold.

Implementing Green Measures: The Long-Term Impacts on Manufacturing

After Diorazio’s introduction concluded, the debate began. Andrews opened the floor to discuss long-term manufacturing for sustainable high-volume oligonucleotides. In particular, he discussed the forecasted effects of implementing green measures in process development and manufacturing and the potential repercussions this may have on CMO dynamics.

- Discover the Potential of Optimised Oligonucleotides for Precision Medicine

- What are the Analytical Challenges of Early-Stage Oligonucleotide Characterisation?

- ?? Listen to an Exclusive Podcast Featuring Biogen to Discover the Challenges Facing Oligonucleotide Synthesis

“It is possible to make some changes to inherited processes, such as looking at minimising and washing reagents, but it can be a bit trickier when working with CMOs,” he explained. Logistically speaking, introducing significant process changes can be easier said than done. As Andrews puts it, “when working with a CMO, you’re trying to fit all the pieces together across different sites, which can be a challenge.”

Often, pharmaceutical companies require a more streamlined and coordinated manufacturing operation. As is the case with Andrews at GSK, “should we want to introduce frozen solution API (Active Pharmaceutical Ingredient), we’d have to purchase it from a CMO in one country and then ship it to our drug product facilities in another country.” Investing in a combined facility to house both drug substance and drug product production would enable an optimised and integrated manufacturing process.

The Future of Sustainable Synthesis for Oligonucleotides: A Toolbox Approach

Conversation then turned to the future of oligo therapeutics, with one audience member inquiring about how best to utilise alternative processing approaches. Olbrich responded by attesting to the need for a toolbox solution. He continued, “most of the big pharma companies that are now entering the arena of high-volume oligo production have a rich history in small molecule manufacturing.” A dynamic and multi-faceted application is integral for sustainable manufacturing. Optimal techniques include solid-phase synthesis, traditional reactor technology, and, as previously mentioned, blockmers.

A dynamic and multi-faceted application is integral for sustainable manufacturing.

The discussion concluded with Andrews observing how “it is a good time to be involved in oligos.” With ample processing technologies available and targeting agents to mitigate volume, the future looks bright for sustainability initiatives in oligonucleotide therapeutics. At Oxford Global, we couldn’t have been more pleased with the turnout for our March biologics Discussion Group. The conversation was engaging, the debate stimulating, and the industry insights invaluable. We will continue our Discussion Group series in April with a session focusing on ‘Accelerating Antibody Engineering with AI/ML & Advanced Computational Tools and Technologies’. Learn more about the Oxford Global Discussion Group series at our Biologics Portal.

Want to find out more about the latest market news and industry insights? Join our Oligonucleotide Chemistry & Therapeutics Symposium and discover the latest in oligonucleotides chemistry, process and analytical development, therapeutics, and antisense therapy.