Exploring the Pinnacle of Pharmaceutical Innovation: Latest Advancements in Small Molecule Drug Formulation

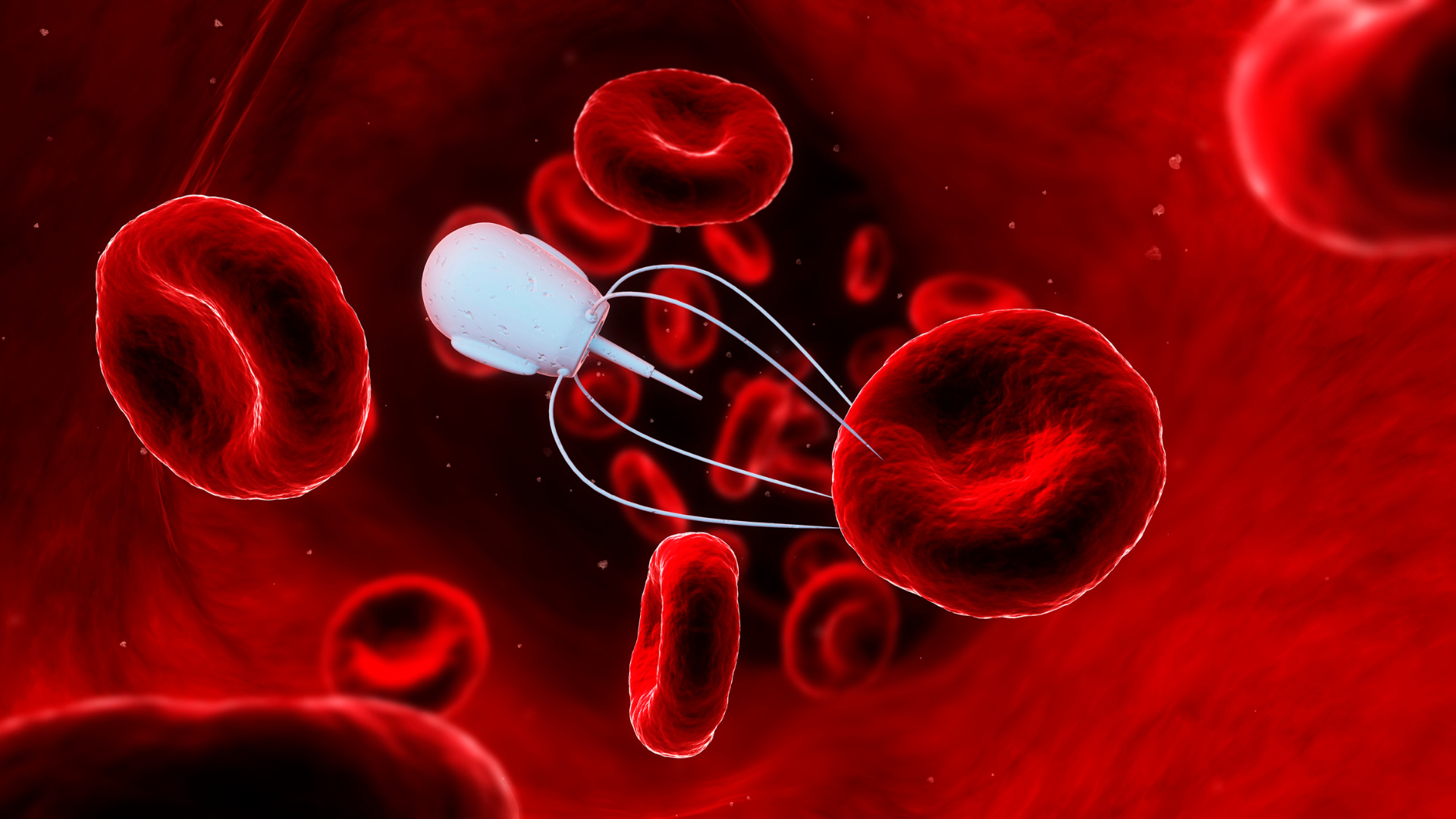

Advancements in Small Molecule Drug Formulation has witnessed remarkable progress in recent years, driven by cutting-edge technologies and innovative approaches. Nanotechnology revolutionizes small molecule drug formulation by leveraging nanoparticles to enhance drug solubility and bioavailability, marking a new era of precision in delivery. New and improved drug delivery systems signify a monumental advancement in the pharmaceutical industry, providing an unmatched degree of accuracy in the timing of drug release, targeting specific tissues, and reducing the potential for adverse effects.

Nanotechnology-Based Formulations: Advancing Precision in Drug Delivery

Nanotechnology has emerged as a groundbreaking paradigm shift within the small molecule drug formulation field. It harnesses the unique properties of nanoparticles and nanocrystals to surmount longstanding challenges associated with solubility and bioavailability of drugs, thereby ushering in a new era of precision in drug delivery.

Nanoparticles, with their minuscule size and high surface area-to-volume ratio, offer several key advantages. First and foremost, they enhance the solubility of poorly water-soluble drugs, which is a common stumbling block in pharmaceutical development. By encapsulating these drugs within nanoparticles, researchers can create stable formulations that readily disperse in biological fluids. This solubility enhancement ensures that a higher proportion of the administered drug reaches its intended target within the body, leading to improved therapeutic outcomes.

Nanotechnology also allows for fine-tuned control over drug release kinetics. By manipulating the composition and surface properties of nanoparticles, scientists can engineer controlled drug release profiles. For instance, a drug may be slowly released over an extended period, maintaining therapeutic levels in the bloodstream, or it may be designed for rapid release at a specific site within the body. This level of precision in drug release kinetics is invaluable, particularly for medications with a narrow therapeutic window or those intended for chronic conditions.

Lipid-based nanoparticles, such as Lipid Nanoparticle (LNP) formulations, exemplify the potential of nanotechnology in drug delivery. These LNPs have garnered considerable attention for their role in delivering small interfering RNA (siRNA) therapeutics. SiRNA is a revolutionary class of drugs capable of silencing specific genes, offering a novel approach to treating genetic diseases. However, siRNA's fragile nature and rapid degradation in the body presented formidable challenges. LNPs act as protective carriers, safeguarding siRNA and facilitating its precise delivery to target cells. This breakthrough has opened doors to the treatment of previously untreatable genetic disorders, marking a monumental stride in the field of molecular medicine.

Advanced Drug Delivery Systems: Precision in Medication Delivery

Advanced drug delivery systems represent a quantum leap in the realm of pharmaceuticals, offering an unprecedented level of precision in drug release, tissue targeting, and side effect mitigation. These systems are engineered to optimise the therapeutic effect of small molecule drugs while minimising adverse reactions.

Among the remarkable innovations in this field are liposomes, micelles, dendrimers, and polymer-based delivery systems. These platforms leverage diverse principles of drug encapsulation, controlled release, and site-specific targeting to enhance the efficacy and safety of small molecule drugs.

Liposomes are microscopic vesicles composed of lipid bilayers. They are well-suited for drug delivery due to their ability to encapsulate both hydrophilic and hydrophobic drugs within their lipid compartments. Liposomes can be tailored to release their cargo at a controlled rate, ensuring sustained therapeutic concentrations of the drug over an extended period. Moreover, their surface properties can be modified to facilitate selective targeting to specific tissues or cells.

Micelles, on the other hand, are self-assembling structures formed by amphiphilic molecules. They are particularly effective in delivering poorly soluble drugs. Micelles solubilize hydrophobic drugs within their hydrophobic cores while exposing their hydrophilic exteriors to the surrounding aqueous environment. This structure not only improves drug solubility but also enables controlled release.

Dendrimers, highly branched synthetic polymers, offer precise control over drug loading and release. Their well-defined structure allows for the attachment of drugs at specific locations, ensuring accurate dosing. Dendrimers can be modified with ligands for targeted drug delivery, enhancing their utility in delivering small molecules to specific cells or tissues.

Polymer-based delivery systems encompass a wide range of materials, including nanoparticles and hydrogels. These systems offer versatility in drug encapsulation and release kinetics. Polymer nanoparticles can be engineered to release drugs in response to environmental cues, such as pH or temperature changes, making them valuable for site-specific drug delivery.

Continuous Manufacturing: A Paradigm Shift in Pharmaceutical Production

Continuous manufacturing processes have ushered in a new era of efficiency and precision in the pharmaceutical industry. In contrast to traditional batch methods, continuous manufacturing involves the uninterrupted flow of materials and processes, offering several distinct advantages in the production of small molecule drug formulations.

The fundamental difference lies in the seamless and continuous nature of operations. In batch manufacturing, ingredients are combined, processed, and isolated in discrete steps. Continuous manufacturing, on the other hand, integrates these processes into a continuous flow, eliminating the need for intermediate storage and reducing the risk of contamination or variations between batches.

One of the primary benefits of continuous manufacturing is the level of control it affords. With real-time monitoring and adjustments, manufacturers can maintain consistent product quality and uniformity. This precision is particularly crucial in the production of small molecule drugs, where even minor variations can significantly impact efficacy and safety.

Continuous manufacturing also contributes to significant cost savings. By streamlining processes and minimizing downtime, manufacturers reduce waste, improve resource utilization, and enhance overall production efficiency. These cost-effective measures can ultimately lead to more accessible and affordable medications for patients.

Conclusion

The integration of nanotechnology into small molecule drug formulation represents a pivotal shift in pharmaceutical science. It empowers researchers to overcome solubility barriers, fine-tune drug release profiles, and unlock new therapeutic possibilities. As scientists continue to explore and refine nanotechnology-based formulations, the potential for breakthroughs in drug delivery and patient care remains limitless.

Advanced drug delivery systems exemplify the synergy of innovation and precision in modern pharmaceuticals. They empower scientists and researchers to optimise drug performance, minimize side effects, and unlock new possibilities in treating various diseases. As these technologies continue to evolve, they hold the potential to redefine the landscape of drug formulation and delivery, ultimately benefiting patients and advancing the field of biotech and pharmaceuticals.

Continuous manufacturing represents a significant leap forward in the pharmaceutical industry, offering enhanced control, cost efficiency, and speed in the production of small molecule drug formulations. As pharmaceutical companies continue to embrace and refine this approach, it has the potential to revolutionize drug manufacturing, making vital medications more accessible and reliable for patients worldwide.

Get your weekly dose of industry news and announcements here, or head over to our Formulation portal to catch up with the latest advances in manufacture and therapeutic delivery. If you’d like to learn more about our upcoming Formulation and Delivery event, click here to download an agenda or register your interest.