The Future of Peptide Chemistry and Sustainability

Peptide drugs have been a growing market for the past decade thanks to their attractive safety profile. With a robust pipeline and an impressive list of new commercial peptides launched in the past few years, it is an industry that is still evolving. The new peptides entering the market are increasingly complex, with the average peptide length having doubled since the 1980s.

This trend for more complex sequences and the requirement for larger volumes of peptides means that traditional development and manufacturing solutions need to be adapted. Whilst trying to meet these needs, producers also have to consider the sustainability of their production process.

Biologics UK: In-Person Conference

One of the highlights of Oxford Global’s Biologics UK: In-Person conference in 2022 was the track dedicated to peptide discovery and peptide therapeutics development and manufacturing, which explored the current outlook for the future of the peptide market, and the routes which are currently open to researchers and developers. Below, we summarise some key insights from two of the most popular presentations on the future of peptide chemistry and sustainability.

Presentation 1: Biopharmaceutical Manufacturing of Next-Generation Peptides

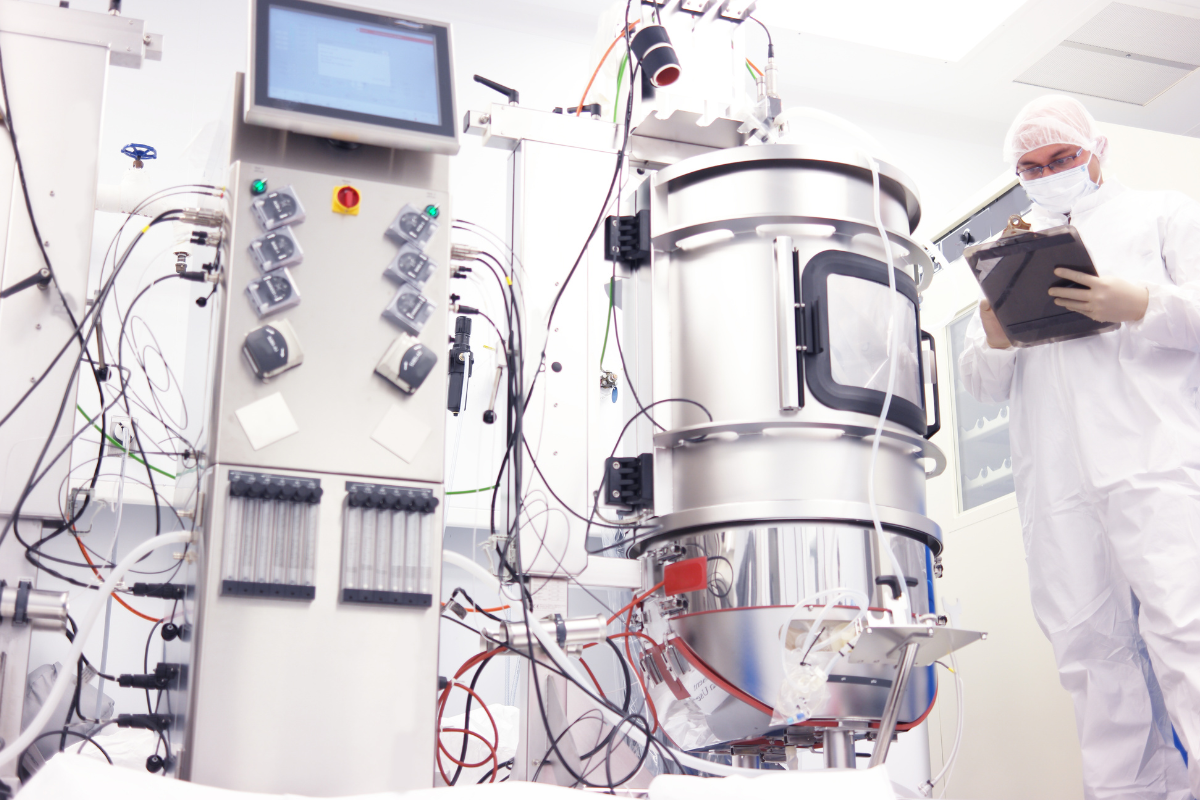

Presented by Daniel Fleischanderl, Head of Upstream Development at Boehringer Ingelheim

There are currently around 150 peptides in active clinical trials. Approximately 80% of these are produced chemically, whilst the remaining 20% are made recombinantly. Fleischanderl presented a compelling case for why recombinant peptide synthesis is an appealing production option, noting that it may be substantially less expensive than chemical synthesis.

The main hurdles for recombinant peptide synthesis include long development times, complex manufacturing processes, expensive purification steps, and low time space yields. However, new technologies such as expression tags and tag-based purification, along with new techniques including automation, modelling, and high-throughput systems, may render recombinant peptide synthesis a more viable option in the coming years.

- The EMA’s Vaccines Working Party: The New Authority on Vaccines

- How AI is Changing the Game for Protein Design

- Biocon’s Biosimilar Difficulties: Successive FDA Rejections Don’t Inspire Hope

Fleischanderl discussed a couple of the tools Boehringer is currently using for the recombinant synthesis of biotherapeutic peptides, including CASPON Technology. This speeds up development timelines by using platform approaches with more efficient affinity purification, including affinity tags and proprietary protease.

There is a range of factors to consider when looking at the feasibility of recombinant peptide synthesis. Fleischanderl commented that “productivity could be significantly improved using a multifermenter screening approach.” No titers could be observed when looking at the expression of smaller peptides in standard microbial systems. By contrast, it becomes easier for these peptides to be expressed using the new tag-based technologies because they become less sensitive to degradation. It was also noted that genome-integrated expression yields significantly lower titers than plasmid-based expression.

The take-home message from Fleischanderl’s presentation was that the production of smaller recombinantly expressed peptides at an industrial scale, in more significant quantities and at favourable costs, may be feasible. However, significant improvements are still needed in the field, but ultimately “the huge potential for cost reduction and limiting environmental impact should justify further development of recombinant peptide synthesis.”

Presentation 2: Efficient and Sustainable Peptide Manufacturing: Challenges and Opportunities

Presented by Olivier Ludemann-Hombourger, Global Director of Innovation & Technology at PolyPeptide Group

Ludemann-Hombourger's presentation examined how manufacturers can combine sustainability and efficiency when producing peptides. He opened by stating that “it’s well-known that peptide chemistry is not the greenest technology”, thanks to the use of hazardous dipolar aprotic solvents and excesses of amino acids and process aids. It is widely acknowledged that there is a genuine need for greener practices to be adopted. However, this is not a straightforward change to implement, as quality, cost, and timelines cannot be compromised; moreover, “the greening of registered manufacturing processes is difficult due to regulatory constraints.”

PolyPeptide has sought to improve its existing practices by reassessing its solid-phase peptide synthesis process. First, they identified the critical process steps: deprotection, washing, coupling, and washing again. Ludemann-Hombourger noted that typically less attention is given to optimising the washing steps, yet poor washing performance can be detrimental to the obtained product quality. Moreover, over 75% of the solvent is often consumed during the washing steps. Thus, more attention must be paid to these washing steps to render the process more sustainable.

PolyPeptide has considered ways in which the washing steps of the solid-phase peptide syntehsis process can be improved. They settled on switching from batch washing to percolation washing, where DMF is added to the top of the resin rather than stirring the resin as DMF is added. In Silico models allowed researchers to evaluate the efficiency of a percolation approach as they reflected key parameters such as bed height and percolation velocity. The model showed that percolation could achieve the desired results much faster, decreasing solvent consumption by more than 50%.

The process was then transferred from modelling to prototypes, which allowed researchers to develop monitoring tools to follow every step of the solid-phase peptide synthesis process. Some technical challenges were encountered, but the overall outcome of the technical experiments confirmed a reduction of over 50% in solvent consumption compared to batch washing.

Therefore, PolyPeptide progressed to industrial implementation, moving from the prototype to large-scale manufacturing. This success means that percolation is now routinely used in production for large-scale applications. “The adoption of greener strategies remains limited on commercial APIs, while the adoption of new solvents and greener disruptive solutions is still progressing but will still take time before being fully implemented in production,” Ludemann-Hombourger concluded.

Biologics UK: An Opportunity to Engage, Educate, and Elevate

The upcoming Biologics UK event is scheduled for 30 to 31 March 2023. It will take place in London and features a dedicated track focusing on novel approaches to peptide chemistry and sustainable peptide manufacturing.

As Europe’s premier meeting for Biologics research and development, the event provides an exciting opportunity to engage, educate, and elevate. Engage with peers and leading solution providers in an exclusive networking environment. Educate yourself with the latest research and innovation in our renowned conference programme. And elevate your biologics research through immersive, discussion-based sessions within a committed community.

Download the agenda today to join prominent leaders and scientists as they share new case studies, innovative data, and exciting industry outlooks.

Join Oxford Global’s annual Biologics UK: In-Person event today. This 3-day conference brings together a panel of prominent leaders and scientists, sharing new case studies, innovative data, and exciting industry outlooks.