Smart Labs: Productivity, Legacy Systems and Digital Fatigue

Our February PharmaTec group bought together a wide array of people working on digitalisation, automation, and informatics to talk about the laboratories of the future.

Leading the session was Angelika Fuchs, who has over ten years of experience in Research Informatics with a focus on human-centric digitalisation in drug discovery. Dr Fuchs is currently leading a global Data Automation team in Roche Pharma Research and Early Development (pRED) Informatics. Her team’s goal is to catalyse digitalisation for Roche’s preclinical labs with innovative and efficient digital solutions automating data capture, processing, analytics, and uploading into FAIR data systems.

Drug Discovery, Productivity and Smart Labs

The field of drug discovery is changing, and the requirements for finding new molecules are increasingly more complex. The industry is moving to a greater focus on rare and complex diseases while facing the challenges of patent expiry and biosimilars. Meanwhile, the speed and productivity of R&D has declined.

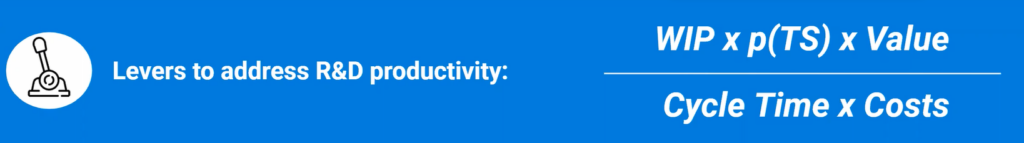

Angelika opened the group by sharing a presentation on ‘building the labs of the future’ and the levers of productivity. She explains that at Roche, “we aimed to consciously identify the levers to boost our productivity. This is captured in this formula (pictured below) that we use."

One of our goals is to increase WIP (work in progress) which is the ability to parallelize as much as possible. For this, automation of both lab processes but also data flows is a key requirement.

In addition we want to increase p(TS) which is the ‘probability of technical success.’ Our goal is to not only do more but focus also on doing the right things. We need approaches to predict which experiments are likely the ones that will give us the biggest insights. In this area, we envision AI/ML methods based on existing data to play a big role in supporting scientists in decisions around molecule design and test cycles.

Finally, the third aspect we focus on from this formula is Cycle Time which is the time you need to move forward in your value chain process. To move quickly from one decision point to the next one requires not only to do a lot in parallel but also getting rid of steps that are unnecessary. To do so, we need to replace manual steps as much as possible but also again investigate where AI methods can better guide or even replace lab work.”

Challenges:

While the aims and goals of future labs are mostly agreed upon and set out, implementing and introducing changes to current systems has proved challenging. While some obstacles are well known, such as the initial set-up costs and space needed, today’s group focused on legacy systems and resistance to digital changeovers.

Legacy Systems:

Trying to keep the legacy systems going is extremely difficult. While we’ve made some progress in identifying and investing in new automation platforms, at the same time, we’ve got other groups that are working on existing data and predictive modelling.

Fausto Artico (Global R&D Tech Head and Director of Innovation and Data Science at GSK) explained that “the major challenge that I see is that there are many legacy systems in operation that were created a long time ago, when big data did not exist.”

Legacy systems use old methods, technology, computer systems, or programs. This typically implies that a system is out of date or needs replacement. A legacy system can also mean that the operating system or hardware platform is no longer supported in some organisations. For example, most systems these days run on either Linux, Unix, or Windows, but many legacy programs run on custom operating systems or the Tandem hardware platform.

Fausto continued, saying that “when you try to integrate and leverage a lot of legacy data, it is incredibly challenging. You are talking about automating, and how much can we automate things in preclinical? From my experience, every company and every subpart of each company is at different stages of progress, but the challenges always start with how we integrate the vast amounts of data that we have but that we cannot leverage today in a very seamless way.”

A representative from AstraZeneca shared that “We’ve made some progress; we’ve even transitioned data into more modern systems. Unfortunately, the companies that make these systems don’t tend to invest in the legacy ones and instead bring out new versions. Trying to keep the legacy systems going is extremely difficult. While we’ve made some progress in identifying and investing in new automation platforms, at the same time, we’ve got other groups that are working on existing data and predictive modelling.

What we lack now is something that brings those two together. So, I don’t think we have that overarching vision. The two groups have some strategies of their own. But we’re trying to start work now on trying to bring those two together because they naturally thought they should bring should be brought together. And we haven’t really got that that vision defined yet.”

Digital Fatigue:

One attendee introduced the idea of ‘digital fatigue to the group’, referring to the feeling people get when they are worn down by the encroaching growth of digital tools into previously manual tasks.

On our side we also observed that legacy systems may even lead to more digital fatigue

The term was well received by the group. A participant commented that “I find this concept of digital fatigue remarkably interesting, coming from a more of an AI/ML background. In fact, it reminds me of a time when you’d complain of fatigue on the shop floor. And that led to a whole science of ergonomics, factory ergonomics, for example. So, will we see some digital workforce ergonomics coming in? Something that makes this transition a lot more comfortable for somebody who’s not traditionally digital-first in their normal job and helps them adapt to some of these changes.”

Angelika Fuchs agreed, stating that these are “key challenges to address to be successful with the lab of the future. On our side we also observed that legacy systems may even lead to more digital fatigue. A big challenge with some systems, especially legacy ones, is that they are not great when it comes to user experience and ease of use. And this of course then leads to frustration when it comes to moving into more digital ways of working. Change management activities need to address this challenge keeping in mind though also costs. Building great user experience requires effort and investment which needs to be carefully balanced with functional requirements.”

Final Thoughts & Conclusion:

The industry is currently following the road to digital and automated labs, but some challenges remain. If you are interested in Smart Labs and automation, join us later this year for our Smart Labs Uk In-Person and Pharma Manufacturing & Automation: Online events.

.png)